It does not matter if it is bright green, yellow, blue or orange paint, flow-vis has become almost the universal way for teams to assess aero parts.

However, Alpine raised a few eyebrows at last weekend’s Italian Grand Prix when it appeared to roll back the clock and do something a bit more old-school with its aero testing.

Instead of using flow-vis to check on a revised low downforce Monza-specific beam wing, it fitted strips of yarn tufts across the rear of the new component, as well as the rear wing main plane (below).

Alpine A523 technical detail

Photo by: Giorgio Piola

This use of tufts seemed to be something that had long been consigned to grand prix racing’s history books, as F1 technology and understanding of airflow has moved on considerably over the years.

However, there was a very good reason for Alpine to go down this route, and it all relates to exactly what kind of aero understanding teams are trying to get from practice running.

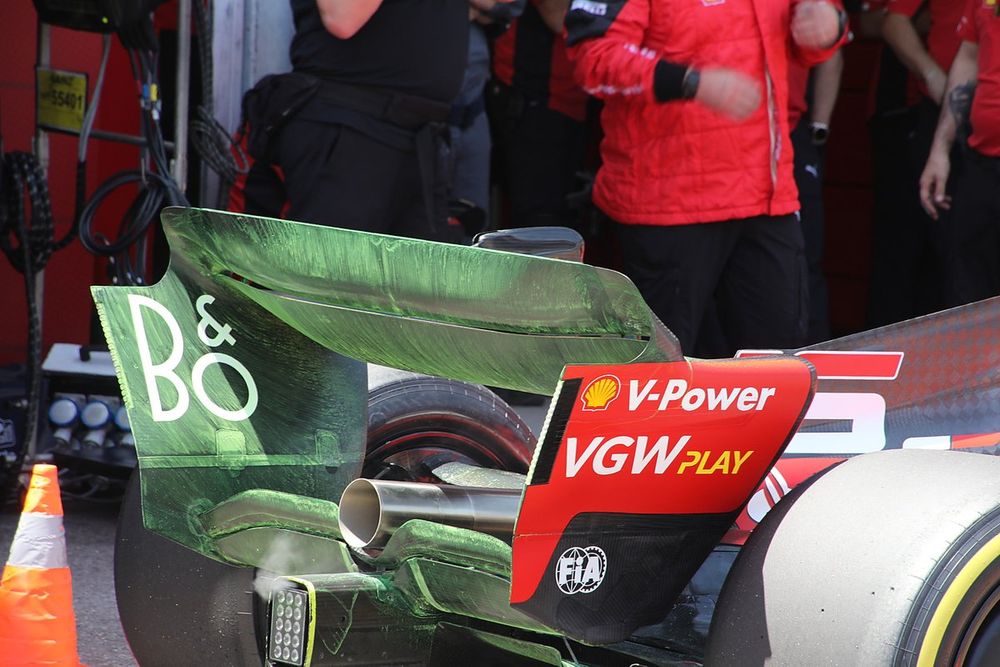

Ferrari SF-23 rear wing with flow-vis paint

Photo by: Giorgio Piola

With flow-vis (see above), the information that teams want to get is how the airflow is structured over the entire car, or how it is impacted by a specific component.

Flow-vis is a fluorescent powder that is mixed with light oil, normally paraffin, before it is painted liberally on a specific part of the car.

When the car is out on track, the flow-vis is moved by the airflow and spreads across the car – leaving behind clear evidence of flow structures and also highlighting areas where there has perhaps been some separation.

When the car is returned to the pits, teams can then take pictures of how the flow-vis has behaved, and this is then analysed by the aerodynamicists to try to better understand if parts are acting in the way anticipated.

This is very much an after-the-event analysis though.

What flow-vis does not give you is how the aerodynamics are working at a specific point out on track, or at a set speed.

The benefit of the tuft testing, as Alpine conducted, is that it can be used to better comprehend how airflow is reacting at every moment out on the circuit.

High-resolution cameras are fitted to the car to focus on the tufts and these capture video footage of how the individual strands are behaving when it is running.

The direction that the strands are flowing in will indicate airflow direction and pressure changes – as well as highlighting potential stall issues – and can be compared at various speeds and different corners.

If the tufts are doing exactly what is wanted when flat out on the straights, but then are doing something totally undesired through low-speed corners, then this will be exposed much better through tuft testing than with flow-vis.

The decision to go with old-school tufts or modern flow-vis is therefore a simple choice between wanting to know what the airflow is doing, or what it has done.

Alpine A523 diffuser detail

Photo by: Uncredited